Sustainable Circular Economy through Artificial Intelligence

KIOptiPack is a BMDF funded research project that aims to improve the circular economy around plastic packaging by using artificial intelligence. To this day, only as much as 11% of recycled materials (consumer waste) is used to manufacture new products. The goal of this project is to overcome challenges associated with such materials (post consumer recyclate) and increase their content in packaging manufacturing. To achieve this goal, the entire cycle from material processing, packaging design, process design, manufacturing process to consumer use and recycling waste management is optimized based on AI algorithms.

More than 50 partners are involved in the project, covering small tech start-ups, middle-sized businesses, research institutions like universities and public institutes, and global leaders in machine manufacturing and production of plastic packaging, such as Arburg, HiPP, LyondellBasell, Remondis, Reifenhäuser, Südpack, Unilever and many more. The field of expertise covers the entire circular economy around plastic packaging and recycling, including waste management, machine manufacturing, plastic packaging manufacturing, AI and simulation.

On 21.-22 November 2022 we participated in the kick-off meeting of KIOptiPack at the RWTH Aachen. The meeting was hosted by the institute for plastics processing (Institut für Kunststoffverarbeitung, IKV) which is also hold the coordination of the project. The two day event included workshops, presentations, and a tour through the IKV labs. Within these two days, we got to know other project partners and exchanged ideas with experts in the field of plastic packaging manufacturing to learn more about their challenges of processing recycled materials.

Beside the impressive extent of the project and fruitful exchange with project partners, a tour through the IKV was one of the highlights of this meeting. It comprised several labs but the most interesting for us was the brand new injection molding lab which still had a ‘new building smell’ in the air. The additive manufacturing lab also seemed out of this world with several 3D-printers in dimensions that reminded us of the labs in the TV series ‘Westworld’.

The most insightful experience though was to touch a little piece of plastic film made from recyclate. It helped to understand the extent of difficulty in processing such materials. The film was very uneven and covered in lumps and bumps. Touching the film also emphasized that the difficulty is not only restricted to the manufacturing process itself, but extends to the entire circular economy which in the end strongly depends on consumer acceptance.

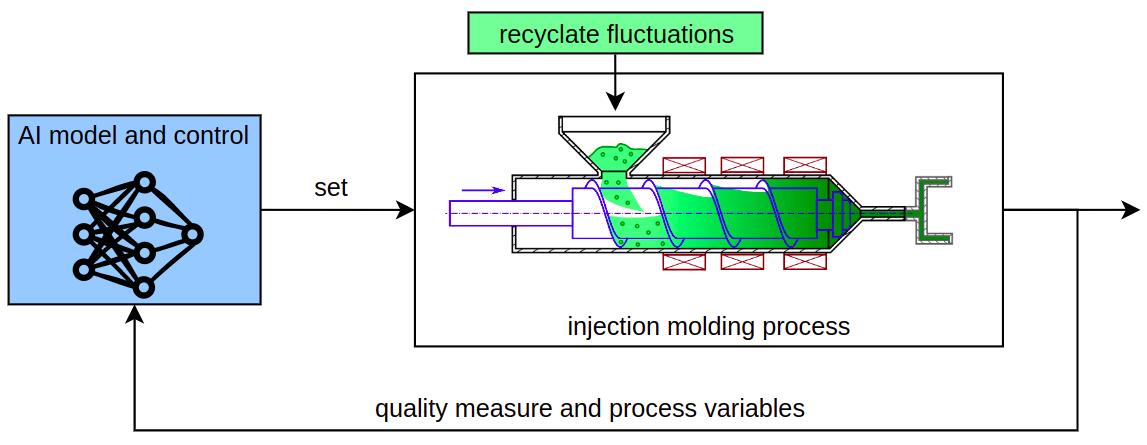

In the next 3 years, we will work on an AI-based inline control of the injection molding process. The goal is to optimize the machine control such that it can compensate for fluctuating material properties which are imposed by the recyclate material. We will closely cooperate with the IKV and other project partners that provide expert knowledge, experimental and simulation data, and an injection molding machine for testing and demonstration purposes.